Installed in CT, MA, RI, NH, and more

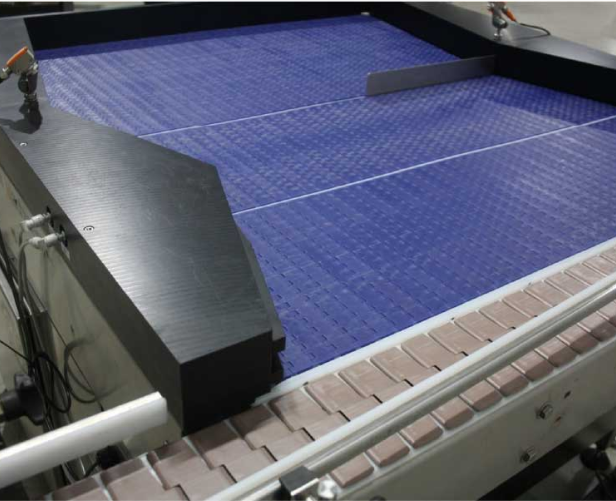

Conveyor System Solutions

Engineered Handling Systems has flexible conveyors systems to fit your specific warehouse needs. Our solutions can maximize your product manufacturing, material handling, and are ideal for any automated storage and retrieval system.

Conveyor Types

There are many different types of conveyors, varying in size and unique capabilities. Depending on your specific needs, one conveyors system may be better than another.

Accumulation Conveyor Systems

Our accumulation conveyor systems are designed to maximize product throughput and regulate workflow lags by temporarily buffering products. These systems save energy, reduce wear and tear on your equipment and pallets, and prevent product damage. Let EHS help you explore the full benefits of accumulation systems for your warehouse or production facility.

Roller Conveyor Systems

Depending on your needs, you might opt for a powered roller, which can move items both horizontally and vertically. They are ideal for small, tight spaces and can handle heavier loads. They are also efficient, quiet, and give users full control over the process. Unlike powered rollers, which are powered by motors, gravity rollers rely on an inclined surface and the force of gravity (and/or push from an operator) to move items along. This economical option can be designed to handle loads of any size, from the lightest loads to the heaviest.

Conveyor System Solutions

Simple yet versatile, conveyor systems are a popular choice in many industries. You can count on EHS for high-quality systems for any industry requiring reliable conveyor solutions.

Improve Processes and Effeciencies

Engineered Handling Systems offers versatile conveyor systems designed to enhance your specific warehouse needs. Our solutions are ideal for automating various processes, improving efficiency, and streamlining operations for many industries.

Material Handling

Our conveyor systems can transport raw materials, parts, and finished products within your facility, reducing manual labor and increasing productivity.

Sorting

Automate the sorting of items based on size, weight, color, or other characteristics. This is essential for logistics and manufacturing, ensuring accurate and efficient sorting processes.

Assembly Line Automation

Conveyors move products through different stages of assembly, minimizing manual handling and boosting production efficiency.

Packaging

Integrate conveyor systems with your packaging process to move products to packaging stations, enhancing speed and consistency.

Inspection and Quality Control

Transport products through inspection stations equipped with sensors and cameras to detect defects and maintain high-quality standards.

Storage and Retrieval

To optimize inventory management, move products to and from storage areas, especially in automated storage and retrieval systems (AS/RS).

Loading and Unloading

Automate the loading and unloading of goods from trucks and shipping containers, increasing efficiency and reducing labor costs.

Waste Management

Transport waste materials and by-products to designated disposal or recycling areas, ensuring a clean and organized facility.

Product Distribution

Distribute products to various locations within a warehouse or distribution center, facilitating order fulfillment and shipping processes.

Inventory Management

Integrate with inventory management systems to track the movement of goods and maintain accurate inventory records.Food Processing

Food Processing

Handle and transport food products in hygienic conditions with specialized conveyors designed for food safety.

Benefits of Conveyor Systems

Efficiency

Streamline processes and reduce manual labor.

Safety

Increase employee safety by automating heavy or repetitive tasks.

Productivity

Enhance productivity by ensuring consistent and reliable product handling.

Cost-Effectiveness

Reduce labor costs and improve overall operational efficiency.